CNC , computer numeric control, machine methods are a type of machining gear controlled by computers. The bottom line is, pc served style (CAD) computer software can be used to generate a style for a component to be machined. That design is translated in to figures and coordinates. The CNC machine process can then “read” these instructions and move the machining resources to the precise coordinates. Ergo, the pieces are cut and designed to the actual requirements of the look, every time.

Alas, there is more to the history as qualified operators also play a role. Let’s have a quick consider the history of CNC machining and one other essential components to effective CNC operations.

Innovations in personal computers and cheaper, better microprocessors shortly followed, starting computer numeric get a handle on to areas of dimensions including to hobbyists. Today, numerous CNC software exists including open resource CNC software.

To be able to begin chopping parts, the machine will need to have recommendations to follow. Understand that G-Code that was standardized in the 1970s? This is a “Get” code that shows the computer numeric control machine where you can get, where point to show, and when to cut. M codes are used to inform the machine when to switch on extra units or add fluids. These requirements are made by CAM application and then loaded onto the machine via flash storage products as well as Wi-Fi in that case equipped.

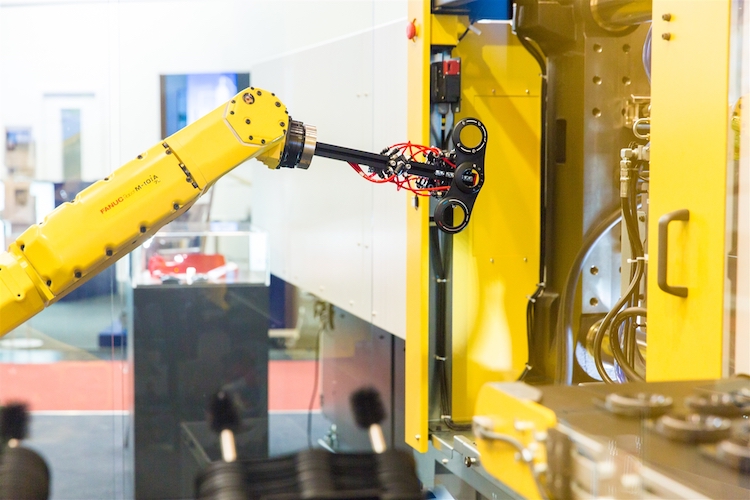

Once the computer numeric control machine is loaded, the CNC owner will have to position the aspec t of be reduce to the machine , planning and obtaining it as needed. From there, the machine agent begins the machine and monitor operations. The CNC machine will follow their recommendations, creating the CNC operator’s job at this time rather easy. However, guidance is a must in case an issue occurs that really needs troubleshooting.

t of be reduce to the machine , planning and obtaining it as needed. From there, the machine agent begins the machine and monitor operations. The CNC machine will follow their recommendations, creating the CNC operator’s job at this time rather easy. However, guidance is a must in case an issue occurs that really needs troubleshooting.

CNC machining means “computer precise get a handle on” machining. It is a fairly new method on the planet of machining which allows for increased effectiveness through larger degrees of automation and by allowing the machine and it’s computer controls to accomplish all of the work. While CNC models are costly and difficult, they quickly purchase themselves by lowering the workload and blocking errors.

The very first important advantageous asset of CNC machining is so it increases automation, eliminating the requirement of an operator for many but a couple of elements of the work. CNC devices could be left unattended for hours as well as times if essential, enabling operators to target on different tasks. This also allows for an organization to keep fewer operators, thereby preserving on overhead.

By removing the operator, security is also improved, since must there be described as a jam or other perhaps harmful machining error, the owner will not be keeping the tool and the thing damaged will be the software itself. CNC products also can work even more quickly than individual machinists, as they are quicker, tougher, and do not require to take breaks. They can be run late at night, when all the employees have gone home, because machines do not require to be concerned about being tired or getting compensated overtime.

The 2nd major advantage to CNC machining is so it provides a precise result each time. Even the most effective human agent can have minor variations between finished results, whereas a Robotics with CNC machines may generate a similar result each and each time it’s run.

This is essential in the modern world of standardized and similar parts, the place where a simple faulty cut could make an entire machine totally unusable. All that’s essential is for an individual program to be developed and located into the machine. Then the machine may toil away at but many perform pieces are required, providing a precise imitation right down to thousandths of an inch each and every time.

The next large advantage to CNC machining is the flexibleness of the machine itself. While individuals are a whole lot more variable and trainable than models, a CNC machine can be totally reprogrammed in a matter of hours to make a very different product. It is hence probable to send back to old programs or deploy new applications whenever a various perform bit is required.

This provides CNC models a large benefit around different products, because they could easily shift to making a very different solution minus the installment of several new areas or perhaps a major overhaul of critical components. And also this guarantees that CNC machines may keep up with client demand, since they could very quickly change from building a part that’s in surplus to a part that is missing must a need arise.

Computer numeric get a grip on devices are used to create all sorts of items and components. CNC models can be used to cut metal, acrylic, and other resources into accurate designs, drill holes, and work areas to specific specifications. They may be used to engrave products, embroider things, reduce leather, and more. From auto pieces, crazy, and products to trophies, engraved tickets, and more, CNC machining is used to generate most of the components used in manufacturing. For example, if you have the iPhone 5c, your iPhone’s decorative layer was CNC’d. If you own an inkjet printer, it is a simple machine that moves the printhead across the X axis based on recommendations sent to it if you push the “print” button.