nbsp;

Pipe Stress Analysis is a critical construct in the technology and maintenance of pipage systems, which are necessity components in a wide range of industries including chemical substance processing, oil and gas, and superpowe multiplication. The term encompasses the mechanical stresses experient by pipes due to various factors, including intragroup pressures, temperature fluctuations, and morphological supports. Understanding and managing these stresses is crucial for ensuring the reliability, refuge, and of piping systems.

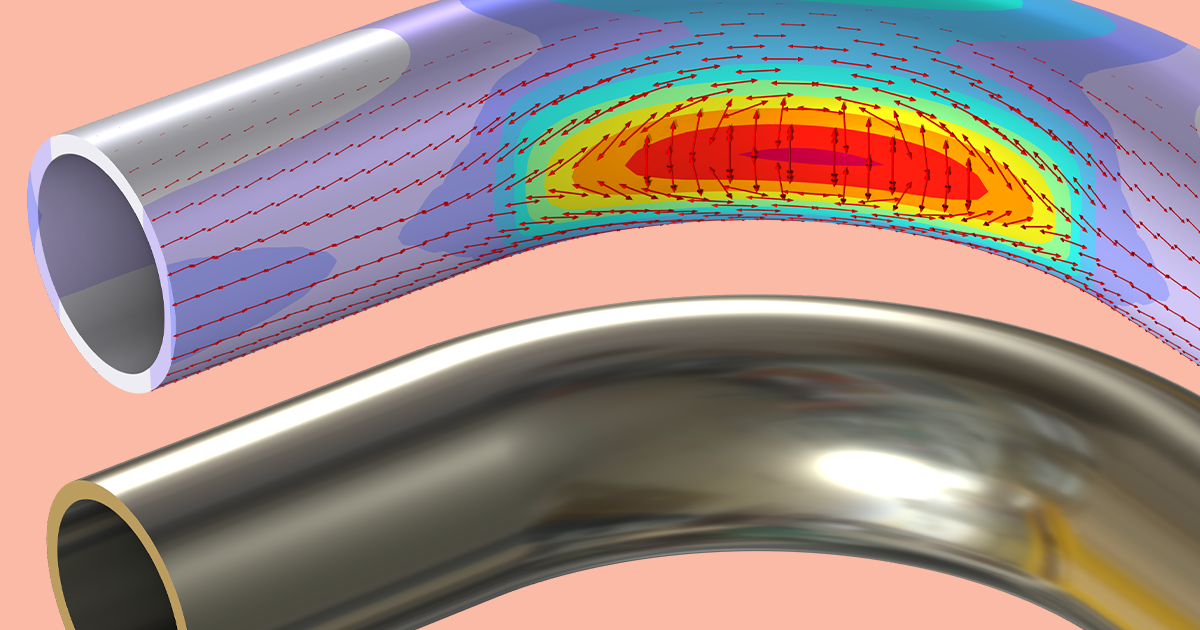

Internal hale is a primary feather factor tributary to pipe strain. As fluids such as irrigate, steamer, or chemicals flow through a pipe, they maintain squeeze against the pipe walls, generating stress stresses. The magnitude of these stresses is influenced by the unstable 39;s squeeze, as well as the pipe 39;s diameter and wall thickness. High-pressure fluids leave in higher stresses, necessitating troubled survival of the fittest of pipe materials to ascertain they can hold out these forces without failing. If the pipe material is inadequate or the plan is flawed, it can lead to issues such as leaks, deformations, or even harmful ruptures, which can pose considerable safety hazards and interrupt operations.

Temperature changes add another layer of complexity to pipe strain. Pipes spread out and undertake in reply to temperature variations, which can present extra stresses into the system. For instance, in environments with vauntingly temperature fluctuations, such as in petrochemical plants or major power propagation facilities, thermic expanding upon and can lead to deflection, warping, or cracking of the pipes if not decent managed. Engineers address these issues by incorporating expansion joints or flexible connectors in the design to suit energy movements and tighten strain concentrations, thereby maintaining the biology wholeness of the piping system.

The subscribe and control systems of pipes are also crucial in managing pipe stress. Pipes are typically pendent by hangers, brackets, and other support structures that hold them in aim and control specific conjunction. Properly designed subscribe systems are necessary to keep unreasonable movement, drooping, or misalignment, which can exacerbate strain concentrations and possibly lead to failures. If the subscribe system of rules is deficient or improperly maintained, it can importantly affect the public presentation and refuge of the pipe system of rules.

External scads, including those from connected equipment, state of affairs conditions, and unstable natural process, further contribute to pipe strain. Equipment attached to the pipe system of rules can introduce additive forces and moments, maximizing the strain seasoned by the pipes. Environmental factors such as high winds or unstable events can cause vibrations and oscillations that impose extra stresses. Engineers must report for these scads during the plan process to see that the piping system of rules is robust enough to handle these forces without compromising safety.

Managing pipe strain in effect involves a combination of strategies and tools. Engineers use stress psychoanalysis software to model various in operation conditions and identify potentiality strain points within the piping system of rules. This enables them to design systems that can hold out expected stresses and keep off potential issues. Material selection is also vital; using materials with high potency and tractability can help extenuate strain-related problems. Additionally, habitue sustenance and inspections are essential for detecting and addressing stress-related issues before they lead to failures. Techniques such as ocular inspections, hale testing, and non-destructive examination help identify signs of try, allowing for well-timed repairs and adjustments.

In summary, pipe strain is a but essential scene of pipe system plan and sustenance. By understanding the personal effects of intragroup pressures, temperature variations, support systems, and external scads, engineers can prepare comprehensive examination strategies to wangle and extenuate pipe try. This go about ensures the dependability, refuge, and of piping systems across various industrial applications, helping to prevent failures and exert operational .