Due to this growth, EPS could be as much as 98 % air, according to their type. XPS foam is created by way of a somewhat various process. Polystyrene deposits are along with different compounds and provided in to an extruder, which creates large quantities of heat and pressure that mix the resources into a thick, fluid mass.

After in that state, it’s delivered through dies that shape its shape since it increases from experience of air and chemical reactions. Both products could be changed to blankets or large prevents to produce components like warmth or appearance or pushed into conforms that generate end services and products like drinking cups.

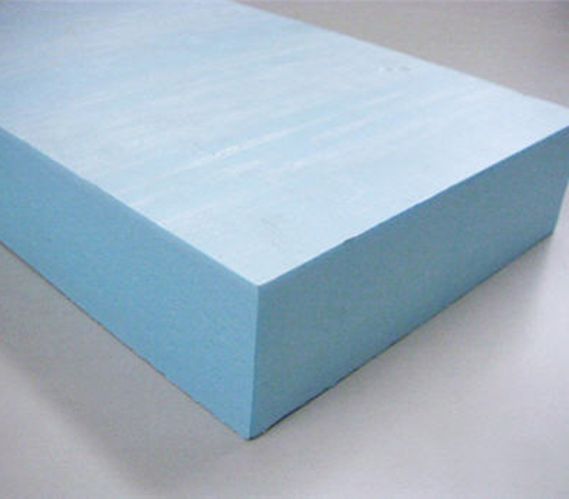

Very similar structurally, both forms of foam have several purposes but their moderate differences let them have unique faculties that produce them suited to different uses. XPS is the denser product of the 2 due to the less-airy structural make-up and is normally more consistent due to the way it’s manufactured. That makes it a great insulating product with a top R-Value, which really is a thermal resistance ranking often employed for polystyrene efficiency materials.

But, as mentioned in a 2003 EPS Molders Association press release named “FTC To Declare Final Notice of Proposed Ruling for R-Value Principle,” XPS uses gasses in their formation that dissipate over time, lowering its long-term padding properties. EPS nevertheless, has “standard air” in the spots within the merchandise, letting it keep their high R-Value on the span of its useful lifetime. The framework of XPS causes it to be slightly more water-resistant than EPS, but the manufacturing of EPS is less expensive than XPS.

There are numerous densities of EPS foam as properly, each with features that make it especially helpful for specific applications. The cheapest thickness EPS varieties, usually about 1 lb, can be manipulated and function as cost-effective products for warmth and personal projects. It can be carefully found in developing and occasionally even in sculpture. Also, it’s found a niche as an inside dessert help for big or detailed tasks and as a cake dummy for decorating exercise or competitions.

The 2nd level EPS density, generally around 2 kilos, is generally the absolute most applied using its greater efficiency functions while still remaining cost-effective. Among typically the most popular employs because of this thickness is really as a hot tub protect since it features a higher R-Value compared to the 1 lb occurrence, with nearly complete resistance from water, humidity and vapors. It will not rot, form, mold or entice fungi, or can any other EPS products. 2 pound thickness EPS provides the mandatory insulation for warm showers at a less expensive than higher densities. It can also be employed for their improved efficiency houses and sporadically businesses utilize it being an outdoor foam signal due to its modification possible and ability to resist the elements.

The highest occurrence EPS products typically used are around 3 pounds, which are most readily useful for quality mattresses made with foam foam padding and construction purposes. There are increased densities accessible but they’re more regularly employed for niche tasks and much less commonly available while the 1, 2 and 3 lb densities.

The good quality 3 lb materials may also be employed as bath, toilet and wall markets in home and creating construction. They are tiled around to produce custom spaces that resist humidity and enhance space. If ideal, products which can be made utilising the different two densities may also be produced utilizing the 3 pound thickness for its increased R-Value and durability. The higher density also posesses higher cost but, and with respect to the use, the added efficiency benefit might not be value the increased cost. Request should always influence material.

Additionally, all EPS foam items shine as an appearance material and flotation foam. Big prevents of EPS have now been applied as flotation foam to go making materials in to area for connections and other underwater construction projects. Floating docks usually use polystyrene as a floatation substance, and some ships employ it in hull structure to steadfastly keep up floatation in the event of emergency. EPS can be frequently utilized in particular flotation products due to its buoyancy. Its moisture-resistant features more raise its simplicity in underwater situations. EPS can also be used in the meals industry as glasses, trays and boxes.