The word is a mathematical term that procedures how far confirmed process deviates from perfection. The key idea behind Six Sigma is that when you can calculate how many “flaws” you’ve in a procedure, you are able to methodically work out how to eliminate them and get as near “zero problems” as possible. To attain Six Sigma Quality, a procedure should create a maximum of 3.4 flaws per million opportunities. An “opportunity” is explained as a opportunity for non-conformance, or perhaps not conference the necessary specifications. This means we must be almost perfect in executing our crucial processes.

You can find three important aspects of quality: client, method and employee. Clients should be the hub of each company: they determine quality. They assume performance, stability, aggressive prices, ontime delivery, company, apparent and correct transaction handling and more. Atlanta divorce attorneys feature that impacts client perception, we realize that just being good isn’t enough.

Delighting our consumers is just a necessity. Because when we don’t get it done, somebody else can! Quality requires people to check out our organization from the customer’s perception, not ours. In other words, we must look at our Processes from the outside-in. By understanding the exchange lifecycle from the customer’s needs and functions, we are able to find what they’re viewing and feeling. With this information, we could identify areas wherever we could put substantial value or improvement from their perspective. People develop results.

Concerning all employees is important to quality. All employees must certanly be trained in the technique, statistical instruments and practices of Six Sigma Quality. Teaching classes contain Champion Education for the Leadership Team, Dark Belt and Natural Strip Instruction for six sigma development task leaders, consciousness instruction for many personnel as well as special instruction for operates like money or sales. Also there’s an importance of inner coaches to support the Six Sigma trip – the therefore named Grasp Black Belts. Grasp Dark Gear, Dark Strip and Green Belt Teaching contain high-level statistical methods, basic quality get a handle on tools and soft-skills tools. Quality could be the duty of every employee. Every staff should be involved, motivated and educated if you’re to succeed.

Often, the inside-out see of the company is based on average or mean-based steps of our new past. Customers do not judge people on averages, they think the difference in each purchase, each item we ship. Six Sigma stresses first on reducing method variation and then on increasing the process capability. Clients value consistent, expected organization functions that supply world-class degrees of quality. This is exactly what Six Sigma strives to produce. Port Welch, GE

Although, General Electrical has made Six Sigma as popular it’s now, the real designer of the idea was Motorola. Motorola – below economic stress inside their TV company in the 1980s – were searching for methods to enhance the grade of their products. In 1986, Statement Smith, a senior manufacture and researcher within Motorola’s Communications Team, presented the concept of Six Sigma in a reaction to increasing problems from the subject revenue power about warranty claims.

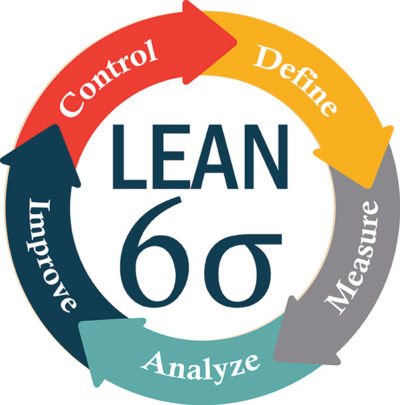

It absolutely was a brand new method for standardising the way in which flaws are relied, with Six Sigma being near perfection. Smith crafted the first statistics and supplements that have been the beginnings of Motorola’s Six Sigma methodology. He took his suggestions to CEO Joe Galvin, who had been struck by Smith’s love and came to recognise the strategy as important to handling quality concerns. Six Sigma became main to Motorola’s strategy of delivering products that have been match for use by customers. Adhering to a popular Six Sigma method (measure, analyse, increase and control) Motorola started their trip of documenting critical procedures, aiming operations to critical customer demands and installing rating and evaluation programs to constantly enhance the process.

Consequently, in 1988 Motorola became the first organization to gain the Malcolm Baldrige National Quality Award. In 1990, Motorola-together with businesses such as IBM, Texas Tools and Xerox-created the concept of Dark Devices (BBs), who would be authorities in using statistical methods. Later, Allied Signal (now Honeywell Global Inc.) and Common Electric Co. properly used and popularised Motorola’s Six Sigma system included in control development.

Arrange Professionals to the Proper Objectives and Targets. Align Professionals to the proper objectives and targets: It begins with elderly executives developing a healthy scorecard of strategic goals, metrics and initiatives to identify the improvement details that will have the most impact on the organisation’s bottom line. Mobilise development teams. Client concentrated task clubs are formed and empowered to get action. Executive method owners encourage Dark Straps to lead well-defined development projects. Six Sigma company development teams use: